Description

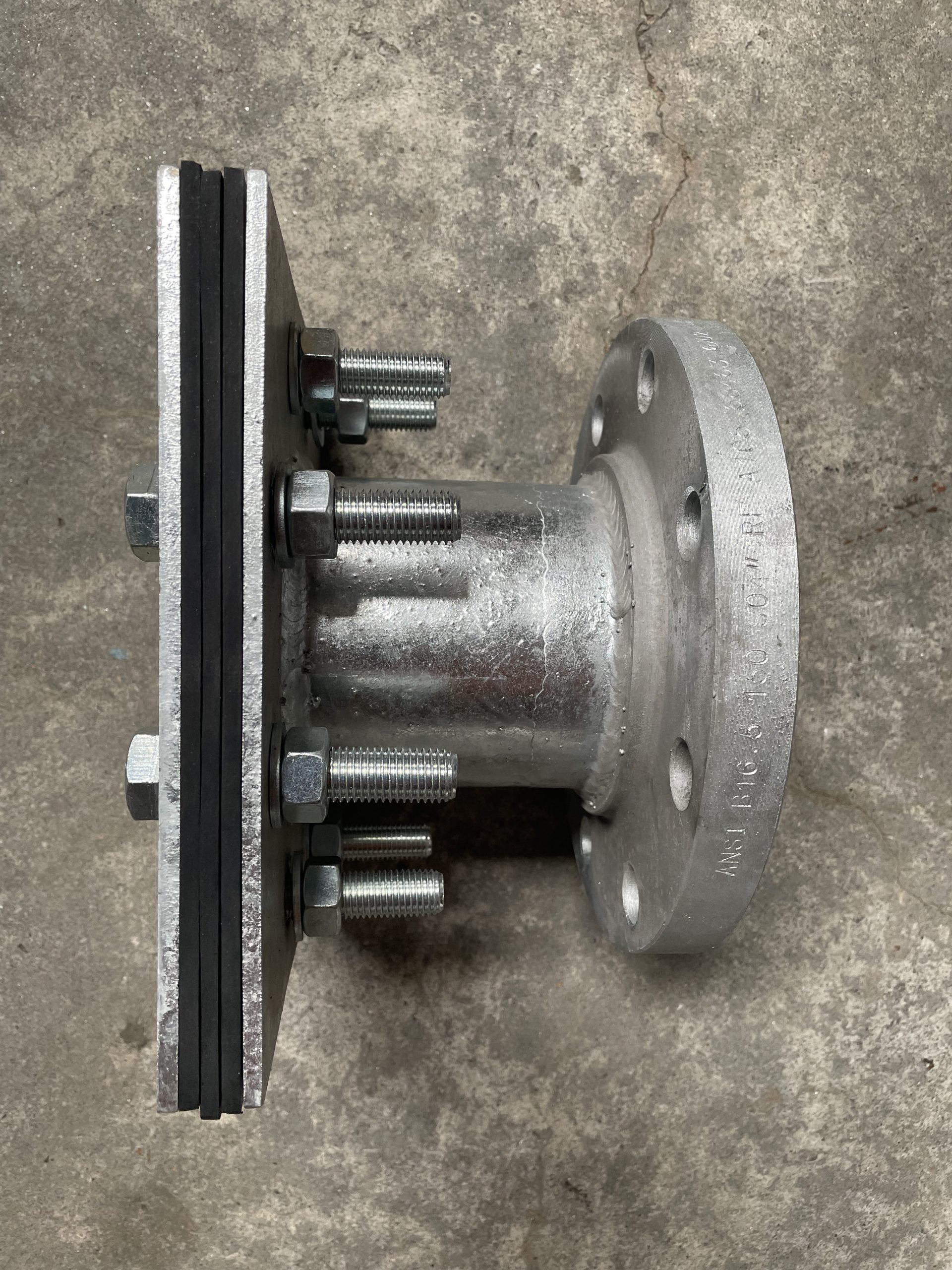

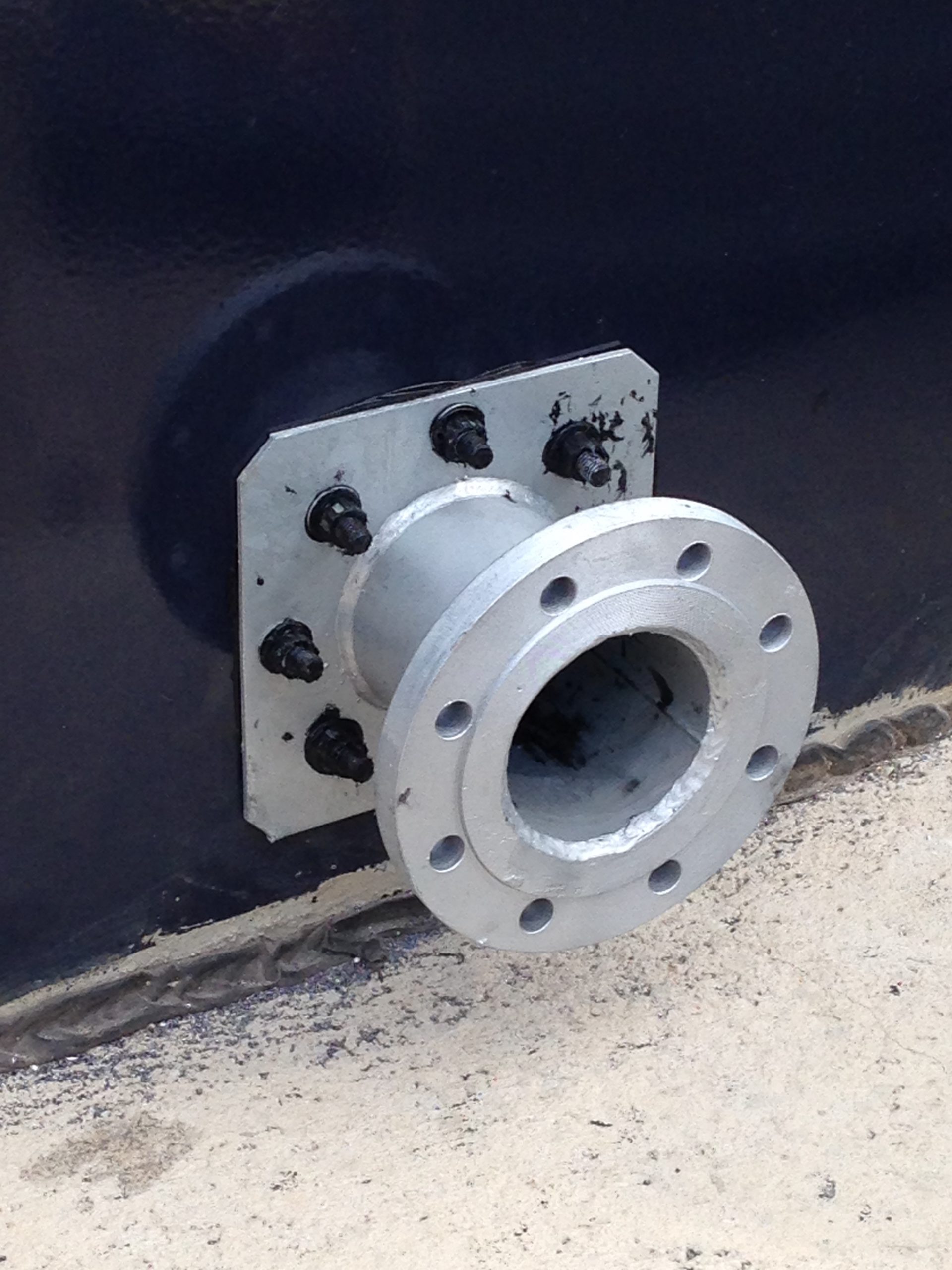

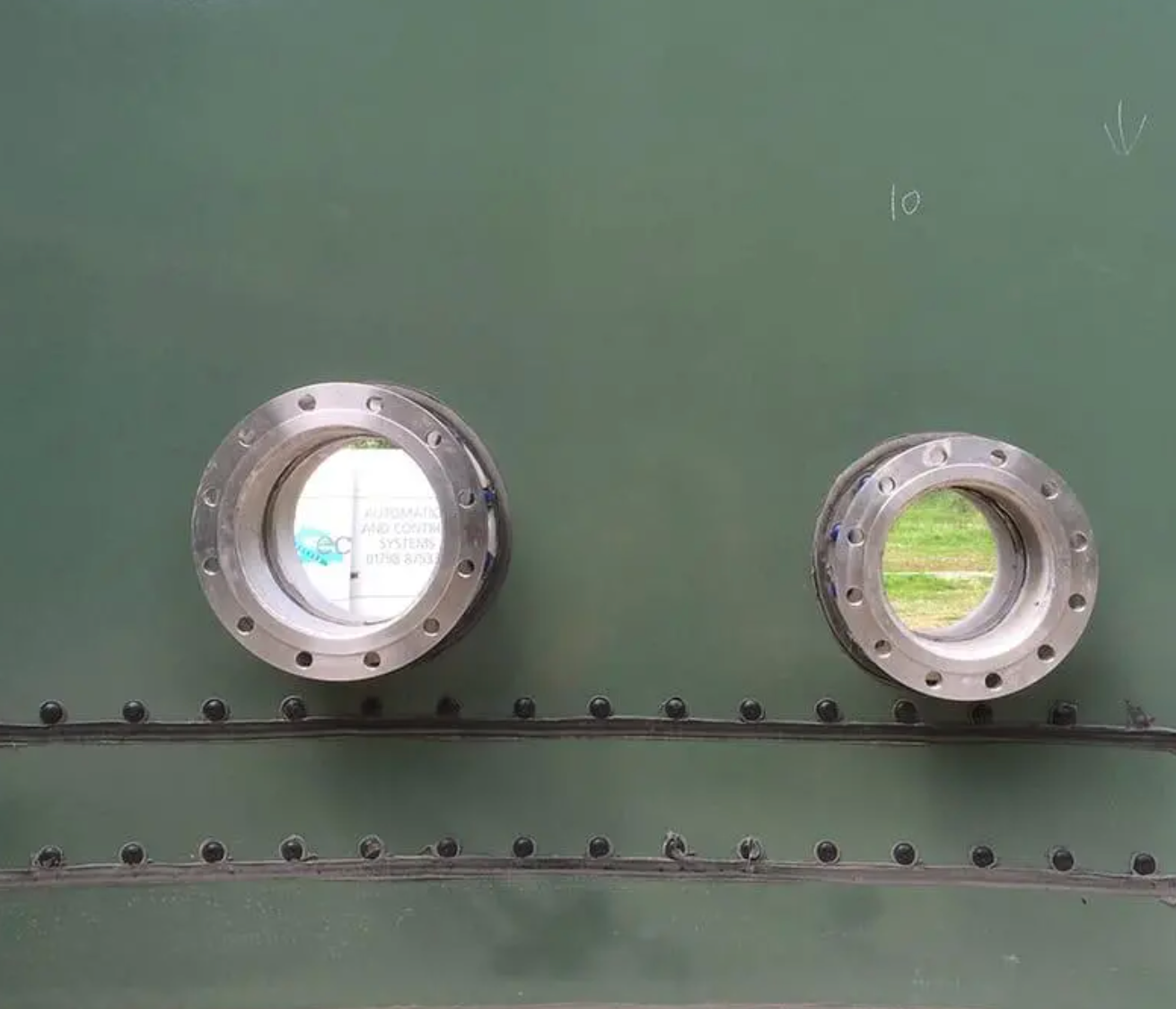

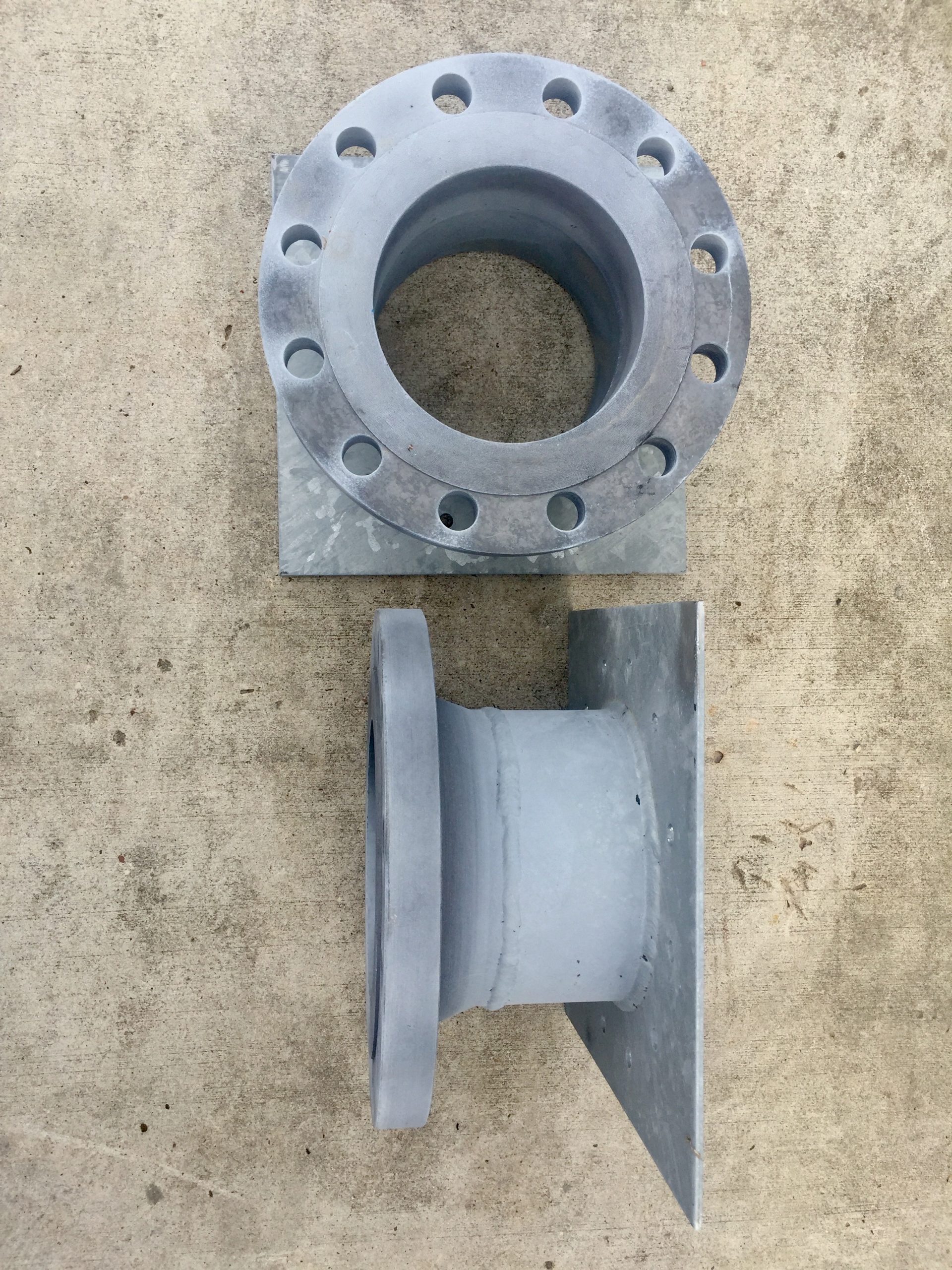

Climate LLC supplies several types, materials, and sizes of nozzles, connectors, and flanges, ranging from stainless steel bolt on, Halcyon Assembly™ vortex inhibitors, PVC schedule 80 and PVC schedule 40 flanges, EDPM, and poly bulkheads. We can custom manufacture nozzles and connectors made for your specifications, as well.

There are many different nozzle, connector, and flange standards to be found worldwide. Common world standards include ASA/ANSI/ASME (USA), PN/DIN (European), BS10 (British/Australian), and JIS/KS (Japanese/Korean).

In most cases these are interchangeable as most local standards have been aligned to ISO standards, however some local standards still differ (e.g., an ANSI/ASME flange will not mate against an ISO flange). Further, many of the flanges in each standard are divided into “pressure classes”, allowing flanges to be capable of taking different pressure ratings. Again, these are not generally interchangeable (e.g., an ANSI/ASME 150 will not mate with an ANSI/ASME 300).

These pressure classes also have differing pressure and temperature ratings for different materials. Unique pressure classes for piping can also be developed for a process plant or power generating station; these may be specific to the corporation, engineering, procurement, and construction (EPC) contractor, or the process plant owner. The ANSI/ASME pressure classes for Flat-Face flanges are 125# and 250#. The classes for Ring-Joint, Tongue & Groove, and Raised-Face flanges are 150#, 300#, (400# – unusual), 600#, 900#, 1500#, and 2500#.

The flange faces are also made to standardized dimensions and are typically “flat face”, “raised face”, “tongue and groove”, or “ring joint” styles, although other obscure styles are possible.

Flange designs are available as “weld neck”, “slip-on”, “lap joint”, “socket weld”, “threaded”, and also “blind”.

Specifications

Pipe flanges that are made to standards called out by ASME B16.5 or ASME B16.47 are typically made from forged materials and have machined surfaces. B16.5 refers to nominal pipe sizes (NPS) from ½” to 24″. B16.47 covers NPSs from 26″ to 60″. Each specification further delineates flanges into pressure classes: 150, 300, 400, 600, 900, 1500 and 2500 for B16.5, and B16.47 delineates its flanges into pressure classes 75, 150, 300, 400, 600, 900. However, these classes do not correspond to maximum pressures in pounds per square inch (psi). Instead, the maximum pressure depends on the material of the flange and the temperature. For example, the maximum pressure for a Class 150 flange is 285 psi, and for a Class 300 Flange it is 740 psi (both are for ASTM A105 Carbon Steel and temperatures below 100F). The gasket type and bolt type are generally specified by the standard(s); however, sometimes the standards refer to the ASME Boiler and Pressure Vessel Code (B&PVC) for details (see ASME Code Section VIII Division 1 – Appendix 2). These flanges are recognized by ASME Pipe Codes such as ASME B31.1 Power Piping, and ASME B31.3 Process Piping. Materials for flanges are usually under ASME designation: SA-105 (Specification for Carbon Steel Forgings for Piping Applications), SA-266 (Specification for Carbon Steel Forgings for Pressure Vessel Components), or SA-182 (Specification for Forged or Rolled Alloy-Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service). In addition, there are many “industry standard” flanges that in some circumstances may be used on ASME work. The product range includes SORF, SOFF, BLRF, BLFF, WNRF (XS, XXS, STD & Schedule 20, 40, 80), WNFF (XS, XXS, STD & Schedule 20, 40, 80), SWRF (XS & STD), SWFF (XS & STD), Threaded RF, Threaded FF & LJ, with sizes from 1/2″ to 16″. The bolting material used for flange connection is stud bolts mated with two nuts (washer when required). In Petrochemical industries, ASTM A193 B7 STUD & ASTM A193 B16 Stud Bolts are used as these have high tensile strength.

Other countries

Flanges in the rest of the world are manufactured according to the International Organization for Standardization (ISO) standards for materials, pressure ratings, etc. to which local standards including DIN and BS…. have been aligned.