Description

HydroChain™ corrosion-resistant composite tanks, chambers and vaults can form the foundation of the stormwater system. The structurally strong modular components are used for detention, retention and/or infiltration.

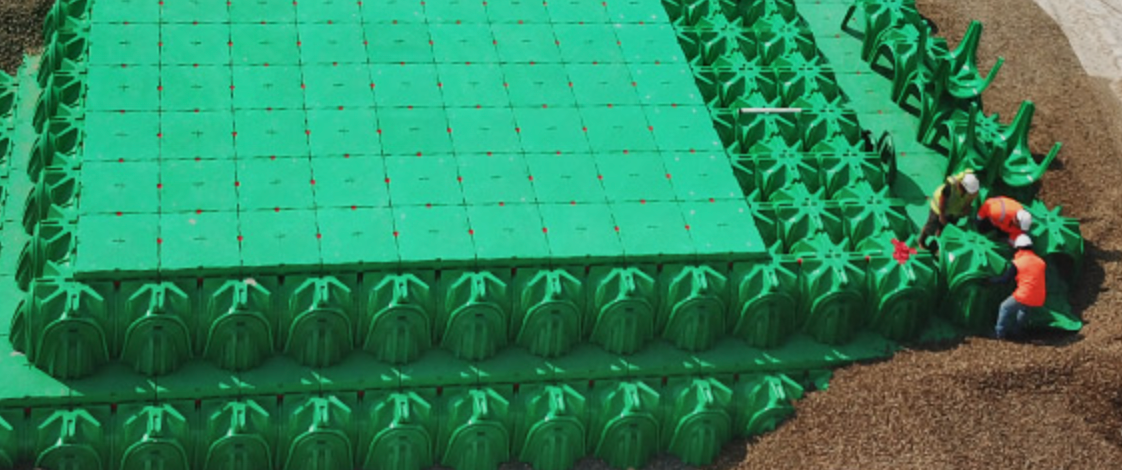

HydroChain™ Chambers:

Eco-friendly composite HydroChain® Chambers are installed surrounded by stone to maximize per-foot infiltration. You can configure the structurally strong chambers for pollutant capture and treatment, and receive 40% greater storage capacity than competitors’ products.

HydroChain™ Vaults:

The HydroChain™ Vault maximizes space and minimizes stone required for large-volume infiltration. Adding end caps, covers, close-offs and locks provides unlimited design flexibility, and creates a system with high-volume capacity per square foot. With the vault, you experience savings at every step, including a 70% reduction of stone backfill.

HydroChain™ Tank System:

Large-diameter fiberglass tanks or field-joined tank sections can be installed in any length or in any number (individually or manifolded) to meet project requirements. Your project benefits from the time-tested corrosion-resistance of fiberglass. The WEKO-SEAL® provides watertight joint seals for the field-joined Xerxes® modular tanks.